Tell us about your Jimny and post some pictures! Please make sure you post in the correct section on the site, this way it keeps the site tidy AND ensures you get a more relevant answer.

Project Rust bucket

- thompo

- Topic Author

- Visitor

-

Public

24 Jun 2015 22:57 - 24 Jun 2015 23:24 #146550

by thompo

Project Rust bucket was created by thompo

Following on from my queries on how to fix it (

www.bigjimny.com/index.php/forum?view=to...=7&id=55843&start=12

) ive finally found some time to put up my thread. :)

Here it is back in Nov 2014, just purchased with the understanding it needs some minor welding for MOT. All i have to do now is drive it 250miles to get a 3Hr ferry crossing in torrential rain and gale force winds

Got it home and stripped the rear out to see what we were dealing with and what it would cost to have it welded...

Needless to say this was the tip of the iceberg!

After some digging i came to conclusion that i wouldnt be paying someone to fix it and id be learning some new skills lol.

This bit just fell off when i removed the bumper

Body mount holed and mounts no longer attached to body

Front end rotten too

Most of the bad stuff removed from the back

Plan of attack was devised,

Aquire a mig welder uncle had hobby spec SIP150 that he never used prefering Oxy/Aceteylne brazing/welding

Learn to weld a little

Repair chassis mount

Repair/ replace body mounts

2.5mm box section with 3mm angles plug welded internally to rear pillars/door frame (double/triple skin areas), remenants of rear panel and internal rear arches rebuilt with 2mm plate and welded to box section. Finally 5mm steel plates with original mount posts welded on. Seems to have worked fine.

Put in new Metal where required.

My method

Area to replace

Clean and remove until you hit solid metal

Repair the easy bits

Template the more difficult

Weld it up

Boot floor/arches patched, Fully down both sides, new jack recess made, lots of new metal added in.

Looks straight forward written here lol

So finally after 3 weeks of grinding, welding, cutting and 3 stitches in my knee due to "grinder incident" it was ready for MOT....

Or so i thought! as id been preoccupied with adding new metal back in id forgot to check normal stuff! Turns out driver side king pin bearing was shot.

It didnt fail to live up to its name of Rust Bucket! Every nut and bolt disentigrated! im not kidding when i say i think i managed to get 1 bolt out using the standard size socket, every other bolt had an undersize socket hammered on, vice grips used or when all of that failed (maybe 6bolts) i had to weld something onto them to get some heat into them and give vice grips some purchase then keep the heat on with a blow torch to finally remove them.

Some 3 hrs later i had 1 side stripped! 20mins later it was back together with new bolts

So MOT then

- at least it didnt fail on any of the stuff i had done

- at least it didnt fail on any of the stuff i had done

Dodgy sill

Suspected crack in chassis - turned out to be surface rust on a previous repair, was cleaned up and seemed sound

so more welding - 3mm plate welded into section of chassis that was looking suspect.

Minor fire

due to hole in floor whilst welding sill

more welding

All done -

I actually forgot to take a picture once everything was sealed and painted before the interior went back in

Thankfully it passed MOT this time

So it had its first outing that weekend

With the Mutt who was the main reason for buying the jimny or so the wife could drive it in the snow

Not sure he gets how its meant to work though!

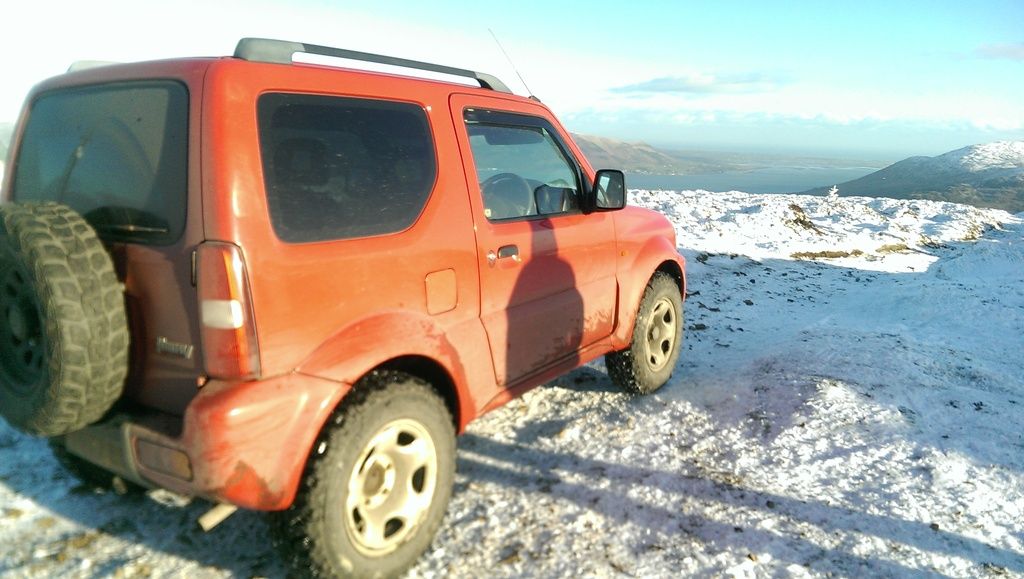

and a few more

First Mod, 16" Grand Vitara wheels and 205/80/16 Insa Dakars seems to be around 29"

Even got some Snow to try them on

Some underbody protection made up - seems a sin to use 10mm Carbon Fiber plate for bashing on rocks but its all we had in the work scrap bin that would do. Interesting to see how long it lasts.

Deffo easier to weld the 6mm brackets up for the transfer box guard than the 1.2mm for body work.

Test fit - Bolts were all properly orientated for final fit.

Ready for some fun

Got a couple further mods done (discreet winch and body lift) ill post when i get time again.

Here it is back in Nov 2014, just purchased with the understanding it needs some minor welding for MOT. All i have to do now is drive it 250miles to get a 3Hr ferry crossing in torrential rain and gale force winds

Got it home and stripped the rear out to see what we were dealing with and what it would cost to have it welded...

Needless to say this was the tip of the iceberg!

After some digging i came to conclusion that i wouldnt be paying someone to fix it and id be learning some new skills lol.

This bit just fell off when i removed the bumper

Body mount holed and mounts no longer attached to body

Front end rotten too

Most of the bad stuff removed from the back

Plan of attack was devised,

Aquire a mig welder uncle had hobby spec SIP150 that he never used prefering Oxy/Aceteylne brazing/welding

Learn to weld a little

Repair chassis mount

Repair/ replace body mounts

2.5mm box section with 3mm angles plug welded internally to rear pillars/door frame (double/triple skin areas), remenants of rear panel and internal rear arches rebuilt with 2mm plate and welded to box section. Finally 5mm steel plates with original mount posts welded on. Seems to have worked fine.

Put in new Metal where required.

My method

Area to replace

Clean and remove until you hit solid metal

Repair the easy bits

Template the more difficult

Weld it up

Boot floor/arches patched, Fully down both sides, new jack recess made, lots of new metal added in.

Looks straight forward written here lol

So finally after 3 weeks of grinding, welding, cutting and 3 stitches in my knee due to "grinder incident" it was ready for MOT....

Or so i thought! as id been preoccupied with adding new metal back in id forgot to check normal stuff! Turns out driver side king pin bearing was shot.

It didnt fail to live up to its name of Rust Bucket! Every nut and bolt disentigrated! im not kidding when i say i think i managed to get 1 bolt out using the standard size socket, every other bolt had an undersize socket hammered on, vice grips used or when all of that failed (maybe 6bolts) i had to weld something onto them to get some heat into them and give vice grips some purchase then keep the heat on with a blow torch to finally remove them.

Some 3 hrs later i had 1 side stripped! 20mins later it was back together with new bolts

So MOT then

Dodgy sill

Suspected crack in chassis - turned out to be surface rust on a previous repair, was cleaned up and seemed sound

so more welding - 3mm plate welded into section of chassis that was looking suspect.

Minor fire

due to hole in floor whilst welding sill

more welding

All done -

I actually forgot to take a picture once everything was sealed and painted before the interior went back in

Thankfully it passed MOT this time

So it had its first outing that weekend

With the Mutt who was the main reason for buying the jimny or so the wife could drive it in the snow

Not sure he gets how its meant to work though!

and a few more

First Mod, 16" Grand Vitara wheels and 205/80/16 Insa Dakars seems to be around 29"

Even got some Snow to try them on

Some underbody protection made up - seems a sin to use 10mm Carbon Fiber plate for bashing on rocks but its all we had in the work scrap bin that would do. Interesting to see how long it lasts.

Deffo easier to weld the 6mm brackets up for the transfer box guard than the 1.2mm for body work.

Test fit - Bolts were all properly orientated for final fit.

Ready for some fun

Got a couple further mods done (discreet winch and body lift) ill post when i get time again.

Last edit: 24 Jun 2015 23:24 by thompo.

Please Log in or Create an account to join the conversation.

24 Jun 2015 23:19 #146553

by minibbb

Replied by minibbb on topic Re:Project Rust bucket

Bloody hell! That was a project and a half!!

Cracking job though- many (including me) would have given up on it!!

Looking great now and is the best of the Jimny colours!

Cracking job though- many (including me) would have given up on it!!

Looking great now and is the best of the Jimny colours!

Please Log in or Create an account to join the conversation.

25 Jun 2015 06:49 #146562

by kirkynut

The underdog often starts the fight, and occasionally the upper dog deserves to win - Edgar Watson Howe.

My Jimny Thread Here: www.bigjimny.com/index.php/forum/8-my-ji...on-continues?start=0

Replied by kirkynut on topic Re:Project Rust bucket

Crickey! That was a scrapper in my mind! Well it was before you learnt to weld!

What an awesome job you've done!

Did you get a new door card and seat after the minor fire? There's a lesson learnt there I guess!

Kirkynut

What an awesome job you've done!

Did you get a new door card and seat after the minor fire? There's a lesson learnt there I guess!

Kirkynut

The underdog often starts the fight, and occasionally the upper dog deserves to win - Edgar Watson Howe.

My Jimny Thread Here: www.bigjimny.com/index.php/forum/8-my-ji...on-continues?start=0

Please Log in or Create an account to join the conversation.

- Tadpole

- Visitor

-

Public

25 Jun 2015 07:41 #146568

by Tadpole

Replied by Tadpole on topic Project Rust bucket

Thanks for sharing 10 out of ten for sticking with it ...... :ohmy:

Please Log in or Create an account to join the conversation.

- markyp2000

- Visitor

-

Public

25 Jun 2015 18:47 #146592

by markyp2000

Replied by markyp2000 on topic Project Rust bucket

A good job well done but you didnt need to undo the 4 bolts behind the hub 100% for effort

Please Log in or Create an account to join the conversation.

- Daft Waders

- Visitor

-

Public

25 Jun 2015 19:58 - 25 Jun 2015 20:23 #146595

by Daft Waders

Replied by Daft Waders on topic Project Rust bucket

Last edit: 25 Jun 2015 20:23 by Daft Waders.

Please Log in or Create an account to join the conversation.

- the_goshawker

- Visitor

-

Public

01 Jul 2015 15:12 #147017

by the_goshawker

Replied by the_goshawker on topic Project Rust bucket

Bloody hell, I will say it again Bloody hell. Mate you deserve a huge pat of the back. If there was a award for BigJimny owner of the week then I think everyone would vote for you. Amazing work

Please Log in or Create an account to join the conversation.

- thompo

- Topic Author

- Visitor

-

Public

02 Jul 2015 22:50 - 30 Nov 2015 21:01 #147105

by thompo

Replied by thompo on topic Project Rust bucket - tons of pics

Cheers guys it was a challenge at times but engine and drivetrain was 100% and id spent enough buying and getting it home so too good to scrap lol. Learnt a lot though.

Still have the front end to do, looking at getting a front end of a breaker or just make something up.

Door card was replaced but not before MOT (look on tester face was priceless), seat and carpet is still toasted but im not too worried, all works as it should lol.

Few more mods ive done.

1" DIY Body lift, cut some 1" CF blocks ("3 dia) and made the tube nuts to thread onto the existing mounts on a mates lathe. (thought i had some better photos of the bits and before and after lift but cant be found!)

We have no Greenlanes as such over here so most (legal) off roading is done competitively through the 4WDNI club (sprints/trials/shiny trials) or more for the craic with the NI Landrover club.

The landrover club is open to all makes and they like to do a lot of this...

Basically get into a forest thats due to be felled (with owners permissions etc) and see how far they can get around a route. If you want to do this you really need a winch....

Ebay special, bought in need of love and a solenoid but price was worth it for the rope alone.

Stripped, cleaned and greased, once i figured out how to short it out to test it it came to life Good buy from ebay lol.

Good buy from ebay lol.

Testing ideas

Took a few measurements and modelled up a plate in CAD so i could put the winch excatly where i wanted it (want to keep the std. bumper). Sent the CAD file to local fabricator and had it laser cut then folded for very little money, plate fits fits well

I welded some 3mm angle between the top and bottom "skins" of the chassis leg to brace it so i could bolt through both "skins" without crushing them to help transfer winch loads over the whole leg.

Plated the crack in the lower bumper too that had been annoying me.

Like a glove - i didnt have to trim the front cross member for the freespool lever but it is tight, might change this when fixing the front end. Tried rotating the lever forwards but would have had to hack the bumper.

got it dirty again

following one of the landrover boys

Replaced the springs with these of Ebay, guy was selling them used and said they were standard height, definately rides smoother with them fitted, old ones were knackered and rear left had snapped!

They are same length as original but one of the fronts is definately thicker gauge, noticed this after i fitted them as the were labelled and it was leaning massively!

The little standard battery was making the winch struggle - made some space for a larger one.

It fits - roughly double the CCA of the standard battery winch works much better.

Next step is to see if i can re route a hard brake line into the master cylinder, it would give me another inch or so space FWD/AFT and let me fit an 096 which is bigger again.

This started out as 2nd battery mod but i dont want the hassle of split charge etc. (really need to get an isolator for the winch!)

Shot from trial type event a couple of weeks back.

Next on the list is make up some recovery points

Get the winch isolated and rig some fixed switches inside and outside so im not relying on the wireless remote.

Fit 30mm spacers (recently bought on here) and see if i can stop the driver side wheel rubbing although i expect the spacers to make it worse lol.

Plans for the summer are to make some new panhard rods ,make rock/tree sliders and see if i can find a budget 2" lift.

Still have the front end to do, looking at getting a front end of a breaker or just make something up.

Door card was replaced but not before MOT (look on tester face was priceless), seat and carpet is still toasted but im not too worried, all works as it should lol.

Few more mods ive done.

1" DIY Body lift, cut some 1" CF blocks ("3 dia) and made the tube nuts to thread onto the existing mounts on a mates lathe. (thought i had some better photos of the bits and before and after lift but cant be found!)

We have no Greenlanes as such over here so most (legal) off roading is done competitively through the 4WDNI club (sprints/trials/shiny trials) or more for the craic with the NI Landrover club.

The landrover club is open to all makes and they like to do a lot of this...

Basically get into a forest thats due to be felled (with owners permissions etc) and see how far they can get around a route. If you want to do this you really need a winch....

Ebay special, bought in need of love and a solenoid but price was worth it for the rope alone.

Stripped, cleaned and greased, once i figured out how to short it out to test it it came to life

Good buy from ebay lol.

Good buy from ebay lol.Testing ideas

Took a few measurements and modelled up a plate in CAD so i could put the winch excatly where i wanted it (want to keep the std. bumper). Sent the CAD file to local fabricator and had it laser cut then folded for very little money, plate fits fits well

I welded some 3mm angle between the top and bottom "skins" of the chassis leg to brace it so i could bolt through both "skins" without crushing them to help transfer winch loads over the whole leg.

Plated the crack in the lower bumper too that had been annoying me.

Like a glove - i didnt have to trim the front cross member for the freespool lever but it is tight, might change this when fixing the front end. Tried rotating the lever forwards but would have had to hack the bumper.

got it dirty again

following one of the landrover boys

Replaced the springs with these of Ebay, guy was selling them used and said they were standard height, definately rides smoother with them fitted, old ones were knackered and rear left had snapped!

They are same length as original but one of the fronts is definately thicker gauge, noticed this after i fitted them as the were labelled and it was leaning massively!

The little standard battery was making the winch struggle - made some space for a larger one.

It fits - roughly double the CCA of the standard battery winch works much better.

Next step is to see if i can re route a hard brake line into the master cylinder, it would give me another inch or so space FWD/AFT and let me fit an 096 which is bigger again.

This started out as 2nd battery mod but i dont want the hassle of split charge etc. (really need to get an isolator for the winch!)

Shot from trial type event a couple of weeks back.

Next on the list is make up some recovery points

Get the winch isolated and rig some fixed switches inside and outside so im not relying on the wireless remote.

Fit 30mm spacers (recently bought on here) and see if i can stop the driver side wheel rubbing although i expect the spacers to make it worse lol.

Plans for the summer are to make some new panhard rods ,make rock/tree sliders and see if i can find a budget 2" lift.

Last edit: 30 Nov 2015 21:01 by thompo.

Please Log in or Create an account to join the conversation.

- thompo

- Topic Author

- Visitor

-

Public

30 Nov 2015 15:15 - 30 Nov 2015 20:56 #157583

by thompo

Replied by thompo on topic Project Rust bucket

Sorry attachhments dont seem to be working ill sort it later

Aother update....

With mot looming again i thought i should check on the rust... :ohmy:

Not good lol.

I think its done...

Front crossmember / body mounts are toast (or swiss cheese?)

Bought another from a scrap yard which it turns out wasnt much better!

but a lot easier to work at off the motor. Anything ropey was cut out and replaced with 2 or 3mm steel.

Decided to remove the top section too just for ease of welding in the new one. Made a couple of templates to pick up holes taht existed in the repair panel so i could i align everything again before lopping the rest of the front off.

Healthy dose of Krust to stop anything i missed and a coat of weldable primer to keep it tidy until ready to paint.

Feels quite a bit sturdier now lol. Still have the inner arches to do where they disappeared from behind the head lights.

Checked the sill too :woohoo:

Which revealed a big hole, a rusty fractured body mount and some floor rust.

Which leads to where i am now

Will have to rebuild the sill area then the body mount/cross member and finally put some new floor in before moving on to inner arches and painting the whole thing with copius amounts of waxoyl where ever i can.

Still mechanically sound and the body is completely rust free externally which is why i dont mind playing around to fix it up.

Hopefully good by the time we get some snow :laugh:

Aother update....

With mot looming again i thought i should check on the rust... :ohmy:

Not good lol.

I think its done...

Front crossmember / body mounts are toast (or swiss cheese?)

Bought another from a scrap yard which it turns out wasnt much better!

but a lot easier to work at off the motor. Anything ropey was cut out and replaced with 2 or 3mm steel.

Decided to remove the top section too just for ease of welding in the new one. Made a couple of templates to pick up holes taht existed in the repair panel so i could i align everything again before lopping the rest of the front off.

Healthy dose of Krust to stop anything i missed and a coat of weldable primer to keep it tidy until ready to paint.

Feels quite a bit sturdier now lol. Still have the inner arches to do where they disappeared from behind the head lights.

Checked the sill too :woohoo:

Which revealed a big hole, a rusty fractured body mount and some floor rust.

Which leads to where i am now

Will have to rebuild the sill area then the body mount/cross member and finally put some new floor in before moving on to inner arches and painting the whole thing with copius amounts of waxoyl where ever i can.

Still mechanically sound and the body is completely rust free externally which is why i dont mind playing around to fix it up.

Hopefully good by the time we get some snow :laugh:

Last edit: 30 Nov 2015 20:56 by thompo.

Please Log in or Create an account to join the conversation.

- Daniel30

- Visitor

-

Public

30 Nov 2015 15:39 #157584

by Daniel30

Replied by Daniel30 on topic Project Rust bucket

Well done with sticking with it, it will be even better to drive once it's done after all that work you have put into it

Please Log in or Create an account to join the conversation.

02 Dec 2015 15:28 #157721

by kirkynut

The underdog often starts the fight, and occasionally the upper dog deserves to win - Edgar Watson Howe.

My Jimny Thread Here: www.bigjimny.com/index.php/forum/8-my-ji...on-continues?start=0

Replied by kirkynut on topic Project Rust bucket

This is great.

I just chuckled re reading it and reading the line "just purchased with the understanding it needs some minor welding for MOT".

Just a little minor welding eh!

Kirkynut

I just chuckled re reading it and reading the line "just purchased with the understanding it needs some minor welding for MOT".

Just a little minor welding eh!

Kirkynut

The underdog often starts the fight, and occasionally the upper dog deserves to win - Edgar Watson Howe.

My Jimny Thread Here: www.bigjimny.com/index.php/forum/8-my-ji...on-continues?start=0

Please Log in or Create an account to join the conversation.

- GraphicX

- Visitor

-

Public

03 Dec 2015 01:36 #157762

by GraphicX

Replied by GraphicX on topic Project Rust bucket

incredible work ! would there be any benefits in treating your car with fish oil or similar to keep the rust at bay a bit ?

Please Log in or Create an account to join the conversation.

Time to create page: 0.202 seconds