![]() The content of any article might be expanded / improved in the future - revisit it sometimes.

The content of any article might be expanded / improved in the future - revisit it sometimes.

![]() Seen a mistake? Know something that isn't written? Edit and change this article yourself!

Seen a mistake? Know something that isn't written? Edit and change this article yourself!

![]() Some images in the article (if present) can be enlarged by clicking on them.

Some images in the article (if present) can be enlarged by clicking on them.

Contents

Introduction

If you off-road a Jimny (or any of the Suzuki classic 4wd vehicles) then you may well end up changing a CV Joint. These are a weak point in the front axle and will break if you are heavy footed or have large tyres fitted.

It is also closely tied in with changing/working on the kingpin bearings so some of the steps are duplicated.

So what are the symptoms of worn/broken CV joints:

- Clicking when in 4WD when turning;

- Banging and snatching of the steering wheel;

- Loss of 4WD transmission to a front wheel;

CV joint information

Identifying type

Suzuki uses three different CV joint types in the Jimny:

- The 1st type is straight forward to purchase on the parts aftermarket, with offerings from several manufacturers.

- The 2nd type is very hard to find on the parts aftermarket, with only one or two products.

- Not much is known about the 3rd type, except that is was used by some (but not all) petrol Jimnys built by Santana in Spain.

- No known aftermarket replacement product exists for the 3rd type.

Suzuki sells genuine CV joints only pre-assembled in a set together with halfshafts for a ************** expensive price (replace the word under the star symbols with an attribute of your choice). Since the left and the right halfshafts have different lengths, the left and right sets are different, although the "left" and the "right" CV joint are identical.

| Type 1 | Type 2 | Type 3 | |

|---|---|---|---|

| Left side set | 44102-81A00 | 44102-84A00 | 44102-82A00 |

| Right side set | 44101-81A00 | 44101-84A00 | 44101-82A00 |

| CV joint | Model used by Suzuki | Balls | Inner splines | Outer splines | Outer case diameter | Inner case diameter | Shaft diameter |

|---|---|---|---|---|---|---|---|

| Type 1 | NTN BJ75LAC | 6 | 19 | 26 | 91.6 mm | 72.6 mm | 19.0 mm |

| Type 2 | NTN EBJ82 | 8 | 29 | 26 | 91.6 mm | 72.6 mm | 21.2 mm |

| Type 3 | AYD 143 Y3 164 | 6 | 20 | 26 | ? | 72.6 mm | 24.5 mm |

![]() CV joint type numbers (like type 1, 2 and 3) are not official Suzuki numbers. It's just a "BigJimny" nomenclature for easier reference.

CV joint type numbers (like type 1, 2 and 3) are not official Suzuki numbers. It's just a "BigJimny" nomenclature for easier reference.

Additional notes:

- CV joint "NTN BJ75LAC" is also sometimes marked as "NTN 75LAC CT9U".

- While NTN EBJ82 (which Suzuki originally sources and sells as their own) has 8 balls, it appears that all aftermarket replacements have 6 balls.

- This is not a critical mismatch - the replacements will fit just fine.

- Only the longevity is questionable (like with any aftermarket part).

- Good luck finding any of these NTN CV joints anywhere on the aftermarket!

- You will probably have to buy aftermarket CV joints from some other manufacturers.

- This is not a critical mismatch - the replacements will fit just fine.

- If anyone knows anything more about type 3 CV joints which are specific to some Santana Jimnys, please contribute to the table above!

- It appears that no aftermarket manufacturer makes equivalent type 3 CV joints.

- If you find one, please add info!

Replacement solutions for type 3 CV joint

- If you determine that your broken CV joint is the abandoned and virtually unsupported type 3, life might still be worth living.

- It is almost hopeless trying to find a used type 3 CV joint, and straight on masochistic asking a quote form Suzuki for original replacement.

- The best long term solution in this case is to convert away from type 3 to either type 1 or type 2.

- Type 1 is the recommended solution, because it has much better aftermarket support than type 2.

- The conversion is dead simple and can be done on one front wheel / axle side only at a time, and on the other at any later point in time.

- The entire conversion consists just of replacing your original halfshaft (which should have 26 splines on the end which enters the differential and 20 splines on the end which enters the CV joint) with a Jimny halfshaft which has the same number of splines (26) on the differential end and either 19 (for type 1) or 29 (for type 2) splines on the CV joint end.

- This is all that it is needed in order to be able to install a type 1 (preferred) or type 2 CV joint as equivalent as it would have been a factory setup.

- The entire conversion consists just of replacing your original halfshaft (which should have 26 splines on the end which enters the differential and 20 splines on the end which enters the CV joint) with a Jimny halfshaft which has the same number of splines (26) on the differential end and either 19 (for type 1) or 29 (for type 2) splines on the CV joint end.

- Note: Left and right halfshafts have different lengths - do not mix them up when obtaining the replacement!

- The cheapest and simplest way of performing this solution should be to buy entire used type 1 or type 2 "CV joint + halfshaft" assembly (for the matching side of the car) from a vehicle scrap yard.

- Even better, obtain just a used halfshaft (if anyone happens to offers it separately) and then buy a brand new aftermarket replacement CV joint.

- While the condition of a used CV joint is a lucky draw and is usually hard to visually inspect, it is very rare for a used halfshaft to be damaged, unless it comes from a beat-up offroader tonka-toy car.

CV joint vs. vehicle compatibility

Compatibility table

Notes about the table below:

- No guarantees are made about the accuracy of the data in the table.

- In other words, your vehicle may be an exception from the classifications which are presented in the table.

- Check the specific CV joint type for your vehicle before ordering!

- The most reliable method is by checking the OEM P.N. of a "CV joint + halfshaft" set with a local Suzuki dealer, based on your vehicle's VIN.

| Engine | Country of manufacture |

VIN code (first 9 characters) |

VIN code (last 8 characters) |

CV joint type |

|---|---|---|---|---|

| G13BB | Japan | JSAFJB33V | ANY | Type 1 |

| G13BB | Spain | VSEFJB33V | ANY | Type 3 |

| M13A | Japan | JSAFJB43V | up to 00186627 up to 40160140 |

Type 1 |

| M13A | Japan | JSAFJB43V | from 00186628 from 40160141 |

Type 2 |

| M13A | Spain | VSEFJB43V | ?ANY? | Type 3 |

| K9K 700 K9K 266 |

Japan | ЈSAFJB53V | ANY | Type 2 |

| K9K 700 K9K 266 |

Spain | VSEFJB53V | ANY | Type 2 |

Pictures of Type 1 CV joints

- Here is the genuine NTN 75LAC CV joint which Suzuki sells

Pictures of Type 2 CV joints

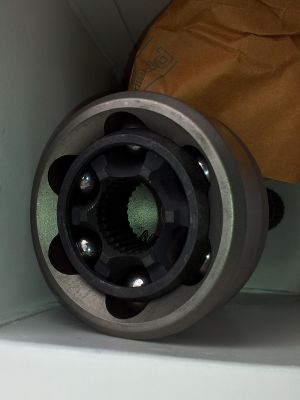

- Above is the genuine NTN EBJ82 CV joint which Suzuki sells only in a super-duper-expensive set together with either a left or a right halfshaft.

- This one was removed from a type 6 Jimny after it fell apart.

- Therefore, there are no pictures of its internals as all the balls and internal pieces fell out during removal of the CV joint.

- However we counted 8 balls which fell out of it on the floor!

- Therefore, there are no pictures of its internals as all the balls and internal pieces fell out during removal of the CV joint.

- This is a compatible 6-ball copy (probably Herth+Buss Jakoparts model J2828040, but Martin needs to verify this)

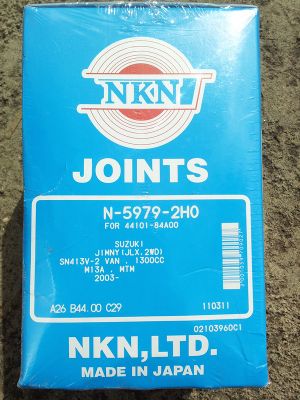

- This is another compatible 6-ball copy, NKN model N-5979-2HO

Pictures of Type 3 CV joints

- Markings AYD 143 Y3 164 - probably genuine OEM

Add more pictures of type 3 if you have them!

Prerequisites

Before embarking onto any work, first comes the overview of the prerequisites.

Required parts

The table

| Part name | Quantity | Suzuki P.N. | Aftermarket replacements | Comments |

|---|---|---|---|---|

| Constant velocity joint |

1 piece | Type 1:

Type 2:

Type 3:

|

Type 1:

Type 2: Type 3:

|

|

| Halfshaft oil seal |

1 piece | 09283-26016 | Any seal with dimensions:

|

|

| Steering knuckle swivel seal |

1 piece | 45120-81A04 | Febest SZOS-001 |

|

| Differential oil |

1.1 - 1.65 litre |

Who cares? | See this and this wiki articles for important details! |

|

| Heavy duty grease(s) |

A handful or so |

? |

| |

| Gasketing sealant |

A small tube |

? |

| |

| A calendar with pictures of (half)naked women |

12 pictures / months |

Probably with portraits of Suzuki's female employees |

|

|

Parts offered in BigJimny Store

The BigJimny Store has the following parts from the above table on sale:

- The following CV joint types (see the dedicated chapter about CV joints above for more info):

- A proper halfshaft oil seal;

- The large swivel/knuckle seal;

- A suitable heavy duty waterproof grease;

- A suitable sealant for king pins;

- Sorry, no calendars with pictures of naked women (nor men for that matter) are in store's offer (yet)!

Notes about greases

General notes about the selection and application of greases:

- A super-durable water-and-mud-and-everything-else resistant grease(s) is essential to protect the steering knuckle assembly, the CV joint and especially the king pin bearings from ingress of grit, water and mud.

- Those contaminants will certainly (rather sooner than later) enter into the steering knuckle.

- Jimny's steering knuckle is poorly sealed by design - this is one of Jimny's main mechanical weaknesses.

- Once inside, the contaminants will immediately (by the course of gravity) proceed towards the lower king pin bearing.

- If the contaminants in the steering knuckle are present in significant quantities, not even the upper king pin bearing nor the CV joint will remain out of their reach.

- If a grease with inadequate water, oil, grit and temperature resistance is used, the contaminants will quickly mix with the grease and eat away the bearings and even possibly the CV joint.

- In certain "dirty / wet" situations, your newly rebuilt, shiny front steering knuckle assembly can get devastated again in just a couple of months of hard use.

- The solution against the ingress of contaminants is not to overfill the bearings, the CV joint or the steering knuckle with blobs of grease in order to physically block their ingress.

- The solution is to use a suitable heavy-duty all-resistant grease in normal quantities.

- The lists of recommended aftermarket greases in the above table is by no means complete.

- Others are welcome to add their own recommendations to the lists!

Additional notes on Maxima 80916 grease:

- This heavy duty lithium grease is the grease of choice on BigJimny shop.

- It has proven itself very well in practice with several Jimny owners for lubricating and protecting king ping bearings, especially in Martin's many years of experience with it.

- Martin should just clarify if this grease is well suitable for CV joints and wheel bearings too (it probably is).

Additional notes on Divinol 23980 grease:

- Forum user Bosanek has had excellent experience with this calcium grease.

- I used it only for the king pin bearings and for the steering knuckle.

- This grease is truly wicked - fluorescent green, super thick, very sticky and gooey, like a "slime from another galaxy".

- The steering knuckle wes opened after a year of hard use (after initially coating the king pin bearings and the steering knuckle with this grease) in order to replace a wheel bearing.

- It was like a mass grave inside.

- However, this Divinol grease still repelled all the grit and sh*t away from itself (and from the king pin bearings) - still keeping the bearings fully and cleanly greased!

- It was like a mass grave inside.

- On the other hand, this Divinol 23980 grease might not be suitable for use in a CV joint nor in a wheel bearing.

- This is just a presumption, because it is very thick and very "gooey" - but it might actually be great in practice.

- Being thick and gooey does not mind at all for the king pin bearings (it's actually desirable), as they do not endure high velocity movements, very high temperatures or high torques and do not need precise lubrication viscosity and other lubrication properties (they "just" pivot around the wheel hub assembly with the wheel).

- Somebody has yet to try this grease in a CV joint and in a wheel bearing and report the long-term effects.

- This is just a presumption, because it is very thick and very "gooey" - but it might actually be great in practice.

Additional notes on Abro LG-990 grease:

- Forum user Bosanek has had very good experience with this fully synthetic lithium grease when used in a CV joint and in a wheel bearing.

- It has a rather high heat resistance (almost 300 C liquifying point) and still claims good resistance against contaminants.

- However, it does not feel nearly as "tough" in the hands as the really wicked Divinol 23980 grease.

- But on the other hand, it is a "safe bet" to keep the sensitive CV joint and the hot-loaded wheel bearing properly greased in all operating conditions.

Required tools

- Standard metric sockets and spanners

- Assorted screwdrivers

- Circlip pliers (external)

- An E10 Torx socket for the vacuum hub head bolts

- A ball joint splitter

- 1" imperial Socket

- G-Clamp or brake piston retractor

- A Big F.....g Hammer (only if you have anger management problems)

CV joint replacement procedure

The Video

Before you read the guide below you may wish to view the video of changing the Kingpin bearings. This shows most of the steps for a CV joint so is a useful reference.

Removing the Caliper and pads

- First of all secure the car.

- Release the wheel nuts and jack up the car and remove the road wheel.

- This then reveals the brake caliper.

- The picture shows the passenger side (nearside) caliper (UK).

- Using a 12mm spanner, release the front caliper bolt (the left is the front of the car in this picture).

- Then loosen the same bolt on the rear of the caliper.

- The caliper then opens up using the rear bolt as a hinge.

- The pads are retained by small spring clips.

- A simple pull on the pads (horizontally away from the disk) should remove them.

- If the pads resist, gently prise out the pads with a small screwdriver - do not remove the spring clips).

- If you require new pads, spring clips or a caliper fitting kit then these are available in the BigJimny Store.

Removing the Brake Disc

- The caliper is held on with two bolts at the rear (see below).

- Release the bolts and tie the caliper to the spring to keep it out of the way.

- Now the front brake disc can be removed.

- If you are lucky it will simply pull off, but if you have problems then there are two M8 holes in the disk hub.

- Simply run two bolts into these holes and the disk will push off the hub.

- The picture shows a bolt being used to push the disk off the hub.

- My disk appeared to be ok on the visible side but the rear showed some bad wear so I will change them as part of this job.

- New disks are available in the BigJimny Store.

Dismantling the Hub

- Now the Freewheeling Hub needs to be removed.

- Suzuki have used Torx bolts to secure these so you will require an E10 socket to remove the bolts.

- With the hub removed, the driveshaft is exposed.

- The driveshaft is retained with a circlip, so use a pair of circlip pliers to remove it.

- This is really fiddly and can be an annoying task.

- Behind the circlip is a rectangular washer that should also be removed.

- Note that I have also marked with white paint the orientation of the freewheeling hub, this is not strictly needed.

- Gently pull the two vacuum hoses for the hub from the knuckle, making sure you note which one connects to each pipe.

- It is essential that you get this correct else the hub will not work again.

- Also note that if you have an ABS equipped vehicle then you will have to remove the sensor.

- I do not have photos of this but the video shows it.

![]() It is really easy to shear the ABS bolt! If you can, soak it for a couple of days previously in penetrating oil.

It is really easy to shear the ABS bolt! If you can, soak it for a couple of days previously in penetrating oil.

- At the rear of the hub, release the small bolts holding the seal and retainer.

- You can see that the swivel hub is covered in oil, a bad sign for KingPin problems.

- Undo the nuts on the steering joints.

- If the joint rotates, then put a jack under the joint and lift the car slightly to lock the joint.

- Using a splitter, split the steering joints (two to do on the passenger side and one on the drivers side – UK).

- Finally, release the KingPin bolts themselves.

- There are two sets, top and bottom and they must not be mixed.

- You can see in the picture that I have marked them up with a letter T.

- If you are doing both sides at once then do not mix them across either!.

- The KingPins are also held in with sticky sealant so you will need to prise them out.

- The hub will now pull off and the driveshaft can be removed.

- Depending on how broken the CV is, the shaft may come out in two pieces.

- The next stage is to CLEAN, CLEAN and then CLEAN again.

- Clean the swivels inside and out, clean the knuckles and make sure all broken CV parts are removed.

- The CV Joint is held on the driveshaft by a hidden C-Clip.

- The only way to dismantle a whole CV Joint (yours may already be in bits if you have really broken it!) is to drive the joint off with a hammer.

- Clamp the driveshaft into a vice and, holding the joint VERY straight, hit the cup with a hammer and drive it off.

- Now put the new C-clip onto the shaft and tap the new joint into place.

Re-assembly

- This is basically the reverse process.

- You may wish to change the king pin bearings and oil seals at this point if you wish.

- If you are changing the large seal then now is the time to put the new one on.

- The confusing part is the order of the seals and rings on the swivel, the picture below is of the correct orientation, note also that the slits in the retainers go to the top.

- Pack the CV with grease (but do not overpack) and re-fit the driveshaft.

- A suitable waterproof grease is available in the BigJimny Shop.

- Grease the new KingPin bearings and insert the top one in the carrier.

- I find the easiest way to grease the bearings is to put them in a polythene bag with some grease and use the bag to squeeze the grease into the bearing, this can be seen in the video. (picture needed here).

- Carefully insert the new bottom bearing and, holding it in place, slide the whole knuckle onto the hub.

- Fill the Knuckle with 100ml of grease, Suzuki recommend only 100ml and not to overfill.

- Now the KingPins need to be inserted, but first they need a bead of sealant around the KingPin.

- Make sure that you have put the correct Kingpin in place.

- Remember you should have marked them when you dismantled them!

- Bolt the Kingpins in and tighten them to the correct torque (18ft/lbs).

- Refit the steering arm (or arms if it is the side with two connections), tightening the nuts to 31ft/lbs.

- Fit the disk and fit the caliper (Caliper bolts 61ft/lbs), brake pads and bolt the caliper down in position (Caliper pin bolt 16/ft/lbs).

- Re-fit the wheel and lower the vehicle.

Torque Settings

Full details of the torque settings can be found in the reference data

Additional reading

Page last edited on 8/01/2021 by user Bosanek