Graham visits Suzuki HQ

From Les ...

I was very disappointed that we were not able to get clearance to drive the Jimnys on Japanese roads. The bureaucratic merry-go-round made it to difficult so in the end I decided to bypass Japan altogether and ship the vehicles direct from Vladivostok to Vancouver. By this time I was flagging a bit and felt that I needed to make a decision and give myself some rest time so that I will be fit enough to under take the last stage of the journey.

Having seen the Jimnys safely tucked up in their container I set off for Greece for a bit of R & R and Graham and Mike boarded a ferry to Japan for a few days site seeing.

From Graham ….

After our eventful journey across Mongolia and and Russia, I was enjoying the civilization of Japan and on a hot humid but sunny day, I took the bullet train from Tokyo to Hamamatsu. I was on my way to visit Suzuki Head Office on behalf of Heaven Can Wait I'm Busy. Its about 160 miles and it took 90 minutes. With five stops that's an average of over 100mph. The trains in Japan are fantastic.

I arrived about 2pm and was met at the Suzuki Head Office by Mr Osamu Shibata, the General Manager of European Sales and Marketing, and Mr Kenta Gotoh, the coordinator of European Sales and Marketing.

Graham and Mr Gotoh and one of the first Jimnys from 1970

We talked for about half an hour and I explained our journey so far and that we were raising money for Save the Children and Oakhaven Hospice. I recounted that the Suzuki Jimnys had performed very well on tracks where most people were driving much bigger 4x4s, and that they had come through their ordeal with only minor problems considering the conditions they had to content with.

One of the first open top Jimnys from 1972

I was given a

tour of the Suzuki museum, which records the history of the Suzuki

company from its beginnings when Mr Suzuki started making weaving

machines, through the time when they started putting engines into

pedal cycles up to the present day.

I was given a

tour of the Suzuki museum, which records the history of the Suzuki

company from its beginnings when Mr Suzuki started making weaving

machines, through the time when they started putting engines into

pedal cycles up to the present day.One of Mr Suzuki's early weaving machines

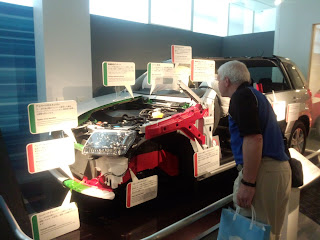

The museum also showed the manufacturing process of a modern Suzuki car, which was very interesting.

Cut away example of a modern Suzuki

The manufacture of the basic components was shown in a 3D cinema.

Me in the 3D cinema

The film included making steel sheet, pressing the steel sheets into body panels, welding the panels together to form the complete body. Casting the engine block and components and moulding the plastic bumpers, then finally the assembly track was shown as a series of full size working models of the various processes involved, until the complete car went into final testing and quality control.

A display of the way plastics are moulded and the end result is a model Suzuki

I left about 5pm and caught the bullet train back to Tokyo, a very enjoyable day.

Me saying goodbye to Mr Gotoh

Our next blog in a few days will reveal the new Stage Four Itinerary so watch out for that.