Difference between revisions of "Universal joint replacement"

Jump to navigation

Jump to search

(Added a new link) |

m (Added the article into gen2 categories) |

||

| Line 161: | Line 161: | ||

{{Edited}} | {{Edited}} | ||

| + | |||

| + | [[Category:Howto - gen2]] | ||

| + | [[Category:Drivechain - gen2]] | ||

[[Category:Howto - gen3]] | [[Category:Howto - gen3]] | ||

Latest revision as of 13:46, 17 January 2021

![]() The content of any article might be expanded / improved in the future - revisit it sometimes.

The content of any article might be expanded / improved in the future - revisit it sometimes.

![]() Seen a mistake? Know something that isn't written? Edit and change this article yourself!

Seen a mistake? Know something that isn't written? Edit and change this article yourself!

![]() Some images in the article (if present) can be enlarged by clicking on them.

Some images in the article (if present) can be enlarged by clicking on them.

Contents

Introduction

- There is an older guide on doing this somewhere, so someone should just copy it here and adjust.

- The topic are universal joints on Jimnys three propeller shafts, and how to replace an universal joint.

![]() It is very important to mount all the prop shafts back exactly as they were originally mounted, because they were balanced for that position in the factory!

It is very important to mount all the prop shafts back exactly as they were originally mounted, because they were balanced for that position in the factory!

Universal joints for Jimny 3

Info on factory fitted universal joints

- The universal joints on all propeller shafts on Jimnys are the same.

- Suzuki's original universal joint P.N. is 27200-83812.

- This same universal joint is also factory fitted to most Jimny 2 (SJ41x and Samurai) vehicle editions, as well as to most Vitara 1 and Vitara 2 vehicle editions.

- The actual manufacturer of that universal joint is Koyo, and the model number is "KC1518CC-1".

- Don't bother finding that exact Koyo product in the aftermarket, as you most probably won't.

- The dimensions of a compatible universal joint have to be 63,8 mm x 25 mm.

- Suzuki's OEM universal joints (and most aftermarket ones which are listed for Jimnys) come without grease nipples.

Reports on removed factory fitted universal joints

- A factory fitted universal joint, removed from a Jimny produced in 2006 was Koyo "KC1518CC-1 H"

- It has no grease nipple.

- It was removed from the rear propeller shaft where it connects to the rear differential after the vehicle traveled around 150 000 km.

- Reason for replacement: It became quite squeaky at low speeds, but still did not exhibit any play.

- When it was taken apart, its internals were found to be quite corroded.

= About aftermarket universal joints

- Practical experience from many users has shown that most cheap aftermarket replacement universal joints (costing cca 10-25 EUR) are of inferior quality and durability compared to the original.

- A low quality universal joint typically lasts for about 6 - 24 months or about 5 000 - 20 000 km or so of on-road driving, and significantly less when driving on all terrain.

- Therefore, it might be a wise investment to buy the much more expensive original universal joint, but then to achieve long term savings on less frequent part replacements and labor replacement costs, as well as saving the nerves.

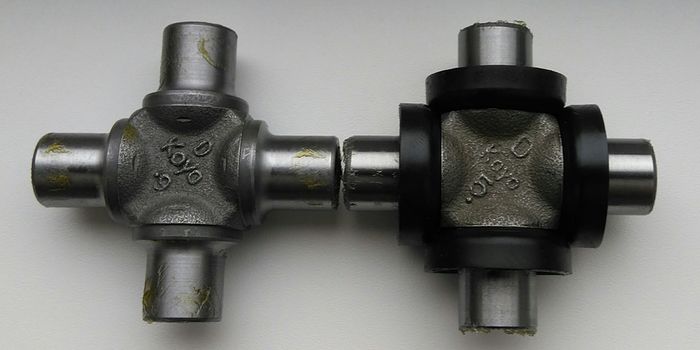

- Many aftermarket universal joints, marketed under various brand names (like Ashika, Blue Print, Japanparts, Niparts, Herth+Buss Jakoparts etc.), are actually produced either by Febest, GMB or Toyo.

- The name of the actual manufacturer is usually stamped on the universal joint itself.

- All three actual manufacturers (Febest, Toyo and especially GMB) are known for producing low quality universal joints.

- If you have to use a non-Suzuki universal joint, it is then recommended to obtain a high quality (expensive) joint of the same dimensions which is meant for industrial or construction machines, as they usually use high quality parts.

- If you manage to find a good quality compatible universal joint with a grease nipple, then better for you.

- Please add your experience into this article.

More info on universal joint Koyo "KC1518CC-1"

- Original Mitsubishi part numbers MR350138 and MR196837 use more-or-less the same universal joint Koyo "KC1518CC-1".

- Those Mitsubishi part numbers are factory fitted universal joints on their Pajero 2 vehicles (and possibly Pajero 1 as well).

- Therefore, they are also high quality parts.

- Reasons why they are "more-or-less the same" as the Koyo joints used in Suzuki 27200-83812:

- All three universal joints have the same dimensions and therefore are mutually interchangeable in practice.

- Mitsubishi MR350138 also has no grease nipple like Suzuki, but it omits the dust/water boots/seals on the universal joint body, which the Suzuki has. On the other hand, Mitsubishi joint's end caps have a seal with double lips, while Suzuki's joint's caps have a seal with a single lip.

- Mitsubishi MR196837 comes with a grease nipple, which fits into a factory drilled hole in one of the four caps. It has no boots on the joint body. The seals in the caps appear to be different than in Mitsubishi MR350138.

- Mitsubishi MR196838 is allegedly identical, apart that it comes without a grease nipple and has no hole for it in any of the four caps.

- Conclusion: Either of those two Mitsubishi universal joints can be used instead of original Suzuki universal joints and are considered to be high quality alternatives, which are superior to most aftermarket replacements.

- Suzuki 27200-83812 and Mitsubishi MR350138 - side by side comparison

- Mitsubishi MR196837

More info on Mitsubishi universal joints:

Universal joints for Jimny 4

Info needed ...

Greaseable or non-greaseable universal joints

- One of the most common causes of driveshaft and U-joint failure is the lack of adequate or proper lubrication.

- There are two types of universal joints - factory sealed (non-maintenance) ones and greaseable ones (with grease nipples).

Non-greaseable joints

- Quality "sealed" universal joints can run for lots of kilometers (even over 150 000 is not uncommon) without any maintenance required.

- However, they will sometimes do so with the needle bearings in them rusted almost completely away.

- One "telltale" sign of an internally rusted universal joint is a squeak or slight grinding noise at speeds below 15 km/h or so.

- This squeak or grinding can sometimes be quite loud, and it can fool you into falsely believing that something is wrong in the (very expensive) differential, gear box or the transfer case!

- Such a joint may have no play or show any outward sign of deterioration.

- However, when taken apart, it's a rusted crumbling mess!

- The most common cause for rust in a sealed universal joint is that a lot of drive lines rarely if ever run at harsh articulation angles.

- Therefore, if a non-maintained universal joint is nearly "straight on" most of the time, you may not know when it has lost its lubricant in certain parts of it (which rarely get "engaged"), which are then corroding away.

- A sealed universal joint can be "converted" into a greaseable one by drilling a hole in its body, cleaning the drill dust and installing a suitable grease nipple.

- However, drilling into them is not such an easy task - sometimes the metal is very tough and/or quite thin, thus making it hard to drill and thread it, and it can be difficult to extract all the drill dust.

- Even if you manage to accomplish all that, it can be quite difficult or even impossible to pump new grease in it, because quality sealed joints can be sealed so well that the old grease just can't exit from the joint past the cup seals.

Greaseable joints

- For normal on-road driving, a greaseable universal joint should be re-greased at least during every engine oil change.

- A greaseable universal joint should be preferably re-greased every time after the vehicle goes through deep snow, deep water or especially through deep mud, as well as through streams of water at high velocities or on filthy dusty roads at high velocities etc.

- The purpose of re-greasing an universal joint is to ensure that its internals are flushed of dirt, salt and other contaminants and that all the bearing cavities are filled with new lubricant.

- Lubrication of universal joints and splined slip yokes requires a good quality NLGI Grade 2 grease with extreme pressure/antiwear (EP/AW) additives and high temperature capability.

- When greasing it, keep pumping until the new grease starts flowing from each of the four bearing boot or seal.

- Do not assume that bearing cavities have been filled with the new lubricant unless flow can be seen around all four bearing seals.

- If new grease does not purge at all four seals, loosen the bearing cap bolts and re-grease until all four cups purge.

- If new grease still does not purge from all four seals, that joint probably has an internal problem and you can count on it getting worn off relatively soon.

- This means to prepare for its impeding replacement by preventively obtaining a new universal joint and keeping it nearby.

- If new grease still does not purge from all four seals, that joint probably has an internal problem and you can count on it getting worn off relatively soon.

- If new grease does not purge at all four seals, loosen the bearing cap bolts and re-grease until all four cups purge.

- Another reason to keep pumping the new grease in for so much is to displace any water that has collected in the joint.

- Also, if a different grease to the old one is being used, make sure that they are mutually compatible.

- If you are not certain in their mutual compatibility, apply a mega-extra quantity of the new grease to purge out as much of the old grease as possible.

- Finally, it is important to thoroughly clean all the exterior surfaces of the joint after re-greasing is finished, as the remnants of the grease on it will attract dirt and grit, and eventually pull them inside the joint ...

- When regularly and thoroughly greased (and with a proper grease), a high quality greaseable universal joint can easily achieve lifetime service longevity.

Additional literature

- A Russian quick illustrated "how to" guide on universal joint replacement in a Jimny 3

- A Russian Jimny user experience on replacing a universal joint

Replacing the damaged boot cover on the flange on the front end of the rear propeller shaft with an original Lada Niva boot:

- Initial replacement guide

- Report after a couple of days of service after the replacement

- Report after two years of service after the replacement

Page last edited on 17/01/2021 by user Bosanek